The Oran W. Nicks Low Speed Wind Tunnel is more than just a giant fan and motor. In the same building there is a full manual and CNC machine shop where the LSWT manufactures many wind tunnel models. However, before the model can be built it must first be designed.

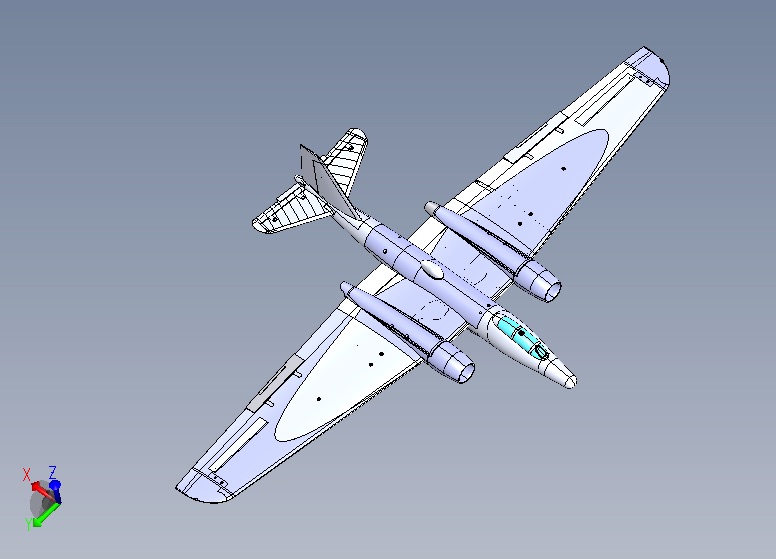

The model design process begins with the customer sending their designs in a format the tunnel can accept. These file types include AutoCad/AutoDesk(2D)(.ipt, .dwg, .dxf), SolidWorks(3D), generic solid model formats (.iges, .step, .x_t), NavisWorks(3D), PDF(2D), or B-size paper drawings. Naturally, 3D SolidWorks or NavisWorks is preferred. Once the full scale model is received, the design engineer(s) begin work on scaling down to a tunnel-appropriate size and simplifying any components that are not critical to aerodynamics.

Much consideration is payed to the interface from the model to the tunnel during the design phase. This is often the biggest design changes from the customer-supplied model and requires the most out of the box thinking. Assembly, part removal, model weight, and more are driving factors in how the model is put together. Luckily, most of the changes from the customer design are internal to the model to allow for interfacing and the external mold line is preserved.

Once a model has passed internal reviews and been accepted by the customer, the designs then travel to the in-house machine shop for fabrication. The wind tunnel staff has been designing and manufacturing models for many years and with their experience comes many satisfied customers.